F-Case edible collagen casings are a brand new product on the market where a tremendous amount of work on production technology has led to the development of casings that answer your manufacturing requirements. The F-Case casings enable efficiency and cost reduction due to stable calibre casing combined with strength and elasticity allowing for production in all types of stuffing machines.

F-Case edible collagen casings eliminate unnecessary steps in the production process and guarantee repeatable weight and appearance of all types of sausage product.

F-Case edible collagen casings are available in a range of specifications to meet your application;

JK- For steamed, smoked and dried sausages such as kabanos/cabanossi, with very good mechanical properties making it ideal for the production of coarse ground sausages.

JP – For cooked or cooked and smoked non-dried products such as frankfurters, wieners and hot-dogs.

JF – For fresh, unprocessed sausages, dried or intended to be grilled, fried or subjected to high temperature.

The F-Case edible collagen casings are available in a range of calibres from 16mm through to 50mm and include the commonly used 22mm, 28mm and 30mm options.

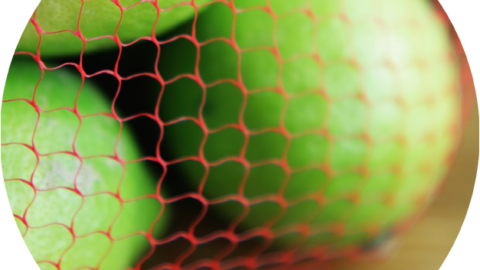

F-Case edible collagen casings are also available in a range of colours from natural though to black and we are currently developing new casing colours to meet the demands of the market.

The F-Case edible collagen casings are sold in the form of shirred sticks of various lengths with either an open end, closed end with a knot or close end with a twist and the casings are packed in caddies, which are secured with foil and then packed in a bulk carton.

Please see below link to F-Case