Oppenheimer has worked for over 25 years to revolutionize the processed meat, dairy and non-food industries with a full range of highly engineered, seamless, tubular plastic casings.

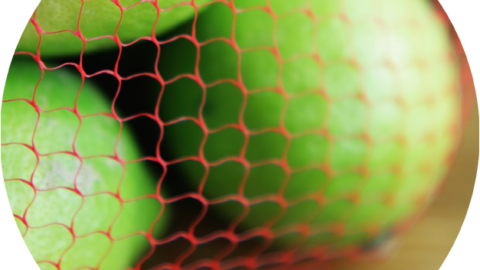

Known for their strength, durability and precise calibre control, Ultra V casings are available in a wide variety of colours and because Ultra V casings can be used on all types of processing equipment they offer a multitude of packaging and printing options to the meat, poultry, dairy and non-food processing industries. With their unique barrier film structure, Ultra V casings ensure quality and freshness, extended shelf life, improved cooking and slicing yields, reduced packaging costs and enhanced aesthetics.

We have ensured that all aspects of the market are met having products (such as Yield casing – Ultra V, Stable Calibre casing – Ultra V SC and Heavy Duty casing – Ultra V HD) designed for specific applications.

Ultra V has used its superior technology to develop and supply casings that show balanced shrink, critical meat cling performance, easy casing removal for slicing, tight square ends for 4×4 production, superior size control, minimum purge, excellent moisture and oxygen barriers and having filled diameter specifications with +/- 1mm tolerances enables significant portion control.

In addition, Ultra V casings are also available printed with your own designs to maximise the marketing impact for your products.